DESIGN AND ANALYSIS OF IMPACT CRUSHERS

crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity Impact crushers: they involve the use of impact rather than pressure to crush An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotorDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT crushing chamber design This combination has proved revolutionary in improving capacity, product quality and in reducing operating and wear costs, ensuring the lowest operating cost per tonne, for a wide range of materials and applications Impact crusher 150 t/h – dolomite crushing Impact crusher PF1620V– limestone crushingPF SERIES IMPACT CRUSHEROPERATING DIMENSIONS TRANSPORT DIMENSIONS 7409273464 • 8008373344 • 4043T Impact Crusher Specifications CRUSHER • 40" diameter rotor x 43" wide (1,016mm x 1,092mm) impact crusher • Lid Crusher Relief System™ with 6" (152mm) raise feature • Feed inlet opening: 43" wide x 28" high (1,092mm x 711mm) • 2 adjustable curtains (apron 4043T IMPACT CRUSHER Screen Machine 512 Impact crushers Breakage is achieved by impact using either hammer action on the individual particles or by sudden impact from a high velocity trajectory High reduction ratios of between 20:1 and 40:1 can be achieved with hammer type impact crushers Only low reduction ratios of about 2:1 can be achieved with kinetic energy type impact TECHNICAL NOTES 5 CRUSHERS Mineral Tech

Construction, Working and Maintenance of Crushers for

dynamic impact When the material is crushed in an impact crusher, the freely falling material first breaks due to dynamic impact by a moving hammer and then the force of impact accelerates movement of the reduced particles toward breaker blocks and/or other hammers for further size reduction Dynamic impact has specific advantages for the mechanism used crushers are of three types namely Cone crusher, Jaw crusher and Impact crusher Fracture occurs in the feed material when the strain developed in it due to sufficiently applied impact forces, pressure or shearing effect exceeds the elastic limit Generally crushers are very rugged, massive and heavy in design“Computer Aided Design of Jaw crusher” 911 Metallurgist mechanical crusher which would help to crush the used juice cans, paint cans and punched sheet metal waste This paper aims to design a crusher that could be installed anywhere and would aid crush of used wastes This paper involves the process of designing the crusher considering forces required for crushing and ergonomicDESIGN OF MECHANICAL CRUSHING MACHINE regarding this design and analysis This project involves processes like design, fabrication and assembling procedures Even though there are many types of the can crusher machine in the market, the completion of the new model provides a more practical usage than previous one KEYWORDS: Design Consideration, Calculation, Size Reduction, CansDesign and Fabrication of Can Crusher ijirset іі) To fabricate recycle bin tin can crusher low cost and time consuming 13 Scope of Work і) Literature review on the knowledge of mechanism design іі) To design the mechanical part of a tin can crusher using CAD software Solid Work ііі) Develop the model tin can crusher using bending process, welding process,DESIGN OF A RECYCLE BIN TIN CAN CRUSHER

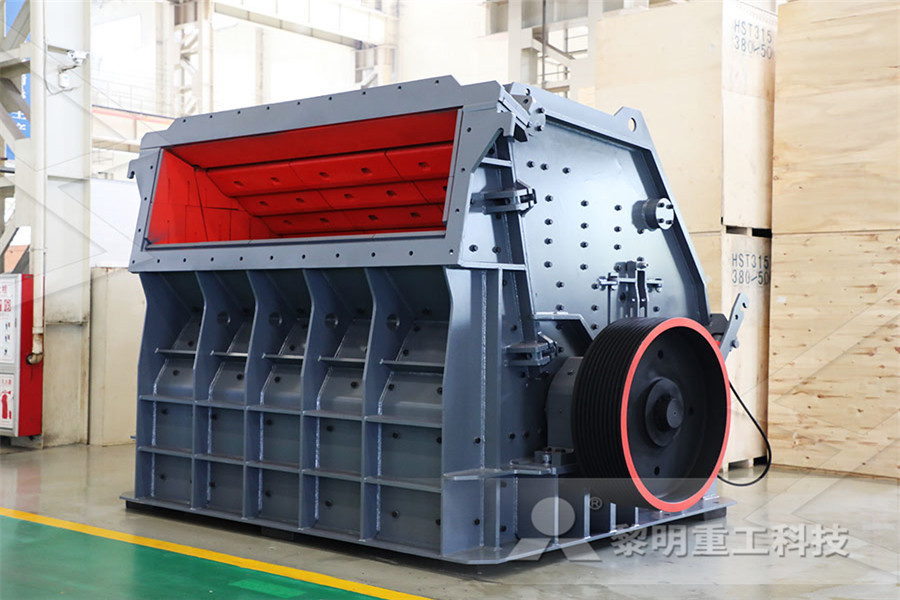

PF SERIES IMPACT CRUSHER

crushing chamber design This combination has proved revolutionary in improving capacity, product quality and in reducing operating and wear costs, ensuring the lowest operating cost per tonne, for a wide range of materials and applications Impact crusher 150 t/h – dolomite crushing Impact crusher PF1620V– limestone crushing levant process parameters, a proven design, highgrade components and optimum materials A high specific throughput, excellent production results and a long service life of the crushers will win you over Pic 1 Impact crushing with high degree of grinding Pic 3 Comparison impact crusher / cone crusher: impact crushing values Prallbr E4043T IMPACT CRUSHER 4043T OPERATING SPECIFICATIONS Height35m 11'6" Length154m 50'5" Width30m 9'10" Total Weight 83,000 lbs 37,650kg 7409273464 • 8008373344 • Directionally reversible, 42" (1,066mm) wide conveyor with impact 4043T IMPACT CRUSHER Screen MachineDesign And Analysis Of Impact Crusher Pdf Crash Pulse Modeling for Vehicle Safety Research Michael S Varat Stein E Husher KEVA Engineering United States of America Paper 501 ABSTRACT Computer simulation, component testing, and sled tests often require the generation of suitable, derived acceleration time histories to define a collision eventDesign And Analysis Of Impact Crusher PdfVSI5X Vertical Shaft Impact Crusher for sale at superior quality and advantages,you can get the detailed Through special optimal design, PDF Download WORD Click Chat Now Online Chat 1012T Tracked Impact Crusher Tesab Engineering 1012T Tracked Impact Crusher The 1012T Impact Crusher is designed to accept a Large Feed Size Impact Crusher Design Pdf nervensonographiech

Construction, Working and Maintenance of Crushers for

dynamic impact When the material is crushed in an impact crusher, the freely falling material first breaks due to dynamic impact by a moving hammer and then the force of impact accelerates movement of the reduced particles toward breaker blocks and/or other hammers for further size reduction Dynamic impact has specific advantages for the mechanical crusher which would help to crush the used juice cans, paint cans and punched sheet metal waste This paper aims to design a crusher that could be installed anywhere and would aid crush of used wastes This paper involves the process of designing the crusher considering forces required for crushing and ergonomicDESIGN OF MECHANICAL CRUSHING MACHINE® NP13™ HSI crusher is the smallest model in the new range of ® NP Series™ HSI crushers built for the secondary and tertiary crushing stages ® NP13™ HSI crusher uses the same design as ® NP15™ ® NP20™ crushers, but it is optimized for slightly smaller capacity requirements® NP13™ impact crusher Outotec іі) To fabricate recycle bin tin can crusher low cost and time consuming 13 Scope of Work і) Literature review on the knowledge of mechanism design іі) To design the mechanical part of a tin can crusher using CAD software Solid Work ііі) Develop the model tin can crusher using bending process, welding process,DESIGN OF A RECYCLE BIN TIN CAN CRUSHER The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these machines Hammer Mill Crusher Grinder 911 Metallurgist

R I140 IMPACT CRUSHER transdiesel

innovation This new generation impact crusher with redefined style and advanced technological design gives improved material flow and production capabilities in quarrying, mining, demolition and recycling applications Incorporating the ® CR032 impact chamber with direct drive and advanced electronic control system the machine provides Stationary singleshaft impact crusher fed by two apron feeders at Cementos Progreso SA, Guatemala Type PB 200/250 CR Throughput rate 1,100 t/h Mobile impact crusher with hydraulic walking mechanism at Martin Marietta, Texas, USA Type PB 250/300 CR Throughput rate 4,500/2,700 t/h Mobile wheelmounted impact crusherIndustrial Solutions Impact crushers ThyssenKrupp levant process parameters, a proven design, highgrade components and optimum materials A high specific throughput, excellent production results and a long service life of the crushers will win you over Pic 1 Impact crushing with high degree of grinding Pic 3 Comparison impact crusher / cone crusher: impact crushing values Prallbr E Due to its favourable design the COMEC impact crusher is suitable for both soft and hard rock Its chamber is easily accessible, which makes the COMEC impact crusher particularly easy to service A long service life due to interchangeable wear plates makes for a highly economical conceptSU E 224Design And Analysis Of Impact Crusher Pdf Crash Pulse Modeling for Vehicle Safety Research Michael S Varat Stein E Husher KEVA Engineering United States of America Paper 501 ABSTRACT Computer simulation, component testing, and sled tests often require the generation of suitable, derived acceleration time histories to define a collision eventDesign And Analysis Of Impact Crusher Pdf

4043T IMPACT CRUSHER Screen Machine

OPERATING DIMENSIONS TRANSPORT DIMENSIONS 7409273464 • 8008373344 • 4043T Impact Crusher Specifications CRUSHER • 40" diameter rotor x 43" wide (1,016mm x 1,092mm) impact crusher • Lid Crusher Relief System™ with 6" (152mm) raise feature • Feed inlet opening: 43" wide x 28" high (1,092mm x 711mm) • 2 adjustable curtains (apron dynamic impact When the material is crushed in an impact crusher, the freely falling material first breaks due to dynamic impact by a moving hammer and then the force of impact accelerates movement of the reduced particles toward breaker blocks and/or other hammers for further size reduction Dynamic impact has specific advantages for the Construction, Working and Maintenance of Crushers for mechanical crusher which would help to crush the used juice cans, paint cans and punched sheet metal waste This paper aims to design a crusher that could be installed anywhere and would aid crush of used wastes This paper involves the process of designing the crusher considering forces required for crushing and ergonomicDESIGN OF MECHANICAL CRUSHING MACHINE regarding this design and analysis This project involves processes like design, fabrication and assembling procedures Even though there are many types of the can crusher machine in the market, the completion of the new model provides a more practical usage than previous one KEYWORDS: Design Consideration, Calculation, Size Reduction, CansDesign and Fabrication of Can Crusher ijirsetImpact Crusher Sample Calculation haagdekode Hammer crusher energy calculation in south africa design calculation for two rotor impact crusheresign knowledge of crusher hammer and disc,kara liu, we must not sloppy the following is the knowledge introduction to the design and calculation of crushers hammer and disc, the size of the diameter of the rotorDesign Calculation For Two Rotor Impact Crusher